February 8-April 2, 2025: With the walls and ceilings gleaming white with fresh paint, we turned our attention to the dusty and dull floor while mentally lining up all the pretty, useful things like cabinets and doors and wood trim that will smooth out the remaining rough edges and make it possible for life to feel calm and orderly.

We sanded out the few bad spots in the slab with a hand tool called a masonry brick. It was surprisingly easy and effective. Then our trusty “weekend warrior” crew set to scrubbing. On our hands and knees. With brushes. Twice.

We flooded the slab, wet-vacuuming and swiffering until the water came up clean.

Next, we mixed up batches of diluted muriatic acid and swept it out, watching it sizzle and foam. It’s a fun and essential step that micro-etches the top layer of concrete so that it readily accepts a coat of sealer. We did this twice, then rinsed four times.

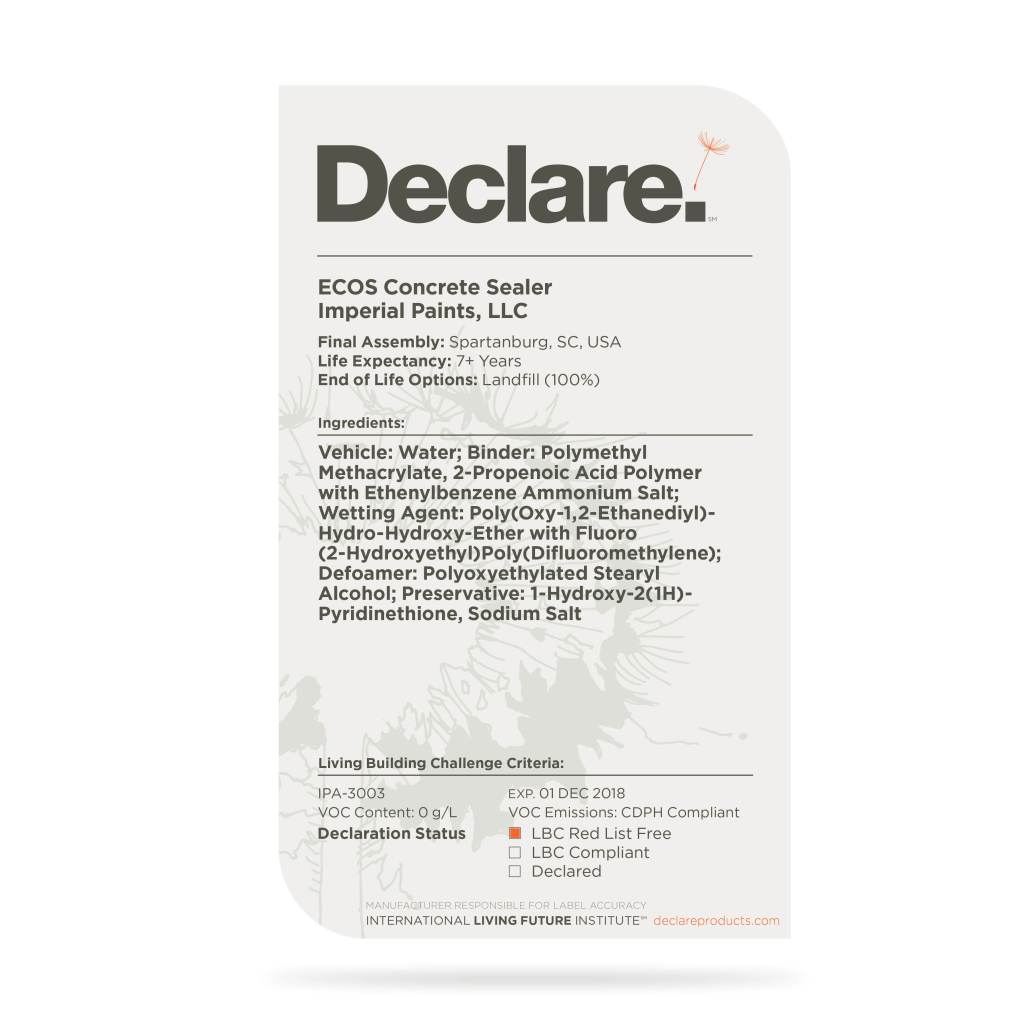

When the slab was good and dry, we brushed out two coats of Ecos Paint Clear Concrete Sealer. This product is non-toxic and low in VOC’s, with a label from the International Living Future Institute’s DECLARE list of healthy building products. My home has the same finish, and it has held up beautifully—-still shiny and bright after 5 years.

The sealer carries the “Red List Free” rating, the highest score in the database. It is free of the chemicals that can harm human, animal, and environmental health.

As if it were finally Christmas, we tore into the boxes and packages of goodies stashed in the garage. For kitchen and bath cabinets, I chose Barker Cabinets for their reasonable price, high quality parts, and green cred:

- Made in America (Oregon)

- Formaldehyde-free 3/4″ 9-ply birch plywood cabinet boxes from U.S. producer Columbia Forest Products

- Solid wood door frames and drawer fronts

- MDF Medium Density Fiberboard Carb Phase 2 low formaldehyde inset panels

- Low VOC clear coat varnish

- RTA Ready-to-Assemble to reduce shipping costs

- DIY friendly to reduce labor costs

Our weekend warriors assembled the cabinet boxes and installed the undermount drawer slides and other hardware. Our finish carpenter, Cale Armstrong, set the cabinets level, plumb, and square. The hand can feel the quality, promising years of ease and satisfying service.

Meanwhile, our friend Eric Wallner was busy in his woodland shop, ripping, routing, drilling, and sanding the parts and pieces that make up his signature Frank Lloyd Wright inspired wardrobes.

Precisely dimensioned for economy and scale. Made from 4×8 sheets of 3/4″ thick 11-ply premium birch plywood. Nary a strip of waste. Pleasing proportions and subtly proportioned details. Piano hinges and smooth stainless steel hardware. A buttery finish that invites touch.

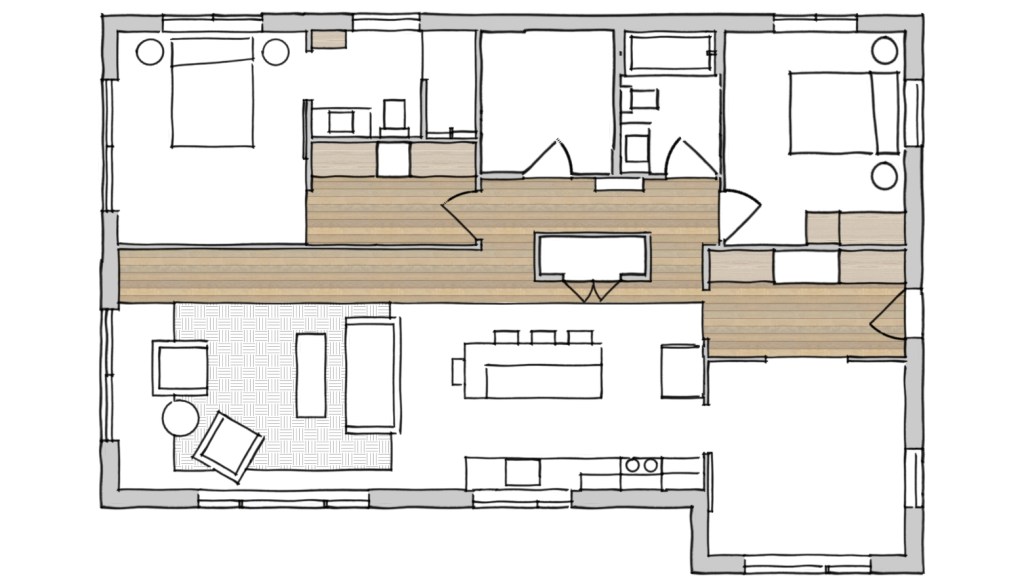

The entry has two 48″ wide units for coats, with a 48″ wide bench between for taking shoes off and on. The west bedroom has two 48″ wide units, with open shelving between for folded clothes. The bathroom for this bedroom has a 24″ wide unit, just 12″ deep, for supplies and towels. The east bedroom has a 48″ wide unit paired with a 24″ unit. They are 72″ tall, on 6″ stainless steel legs.

Open above, and lightly touching the floor, these cabinets replace conventional boxy closets, lending a more spacious and artful feeling to the rooms they so elegantly serve.

A cedar strip wood ceiling finishes the dropped soffit we built to house ductwork. For how and why see my previous blog post Interior Framing.

The cedar strips cantilever 12 inches beyond the soffit (stiffened with plywood backing) to create a light shelf in the Frank Lloyd Wright tradition. Hidden, a dimmable LED tape light bounces light off the drywall ceiling to create a pleasant glow. Recessed downlights punch through the soffit, casting halos of light on the wall.

Recessed downlights are black squares in the cedar ceiling. They are white circles in the drywall ceiling. Super-quiet and completely non-descript white fans in the living room, dining room, and each bedroom keep the air moving.

For window sills, we chose 2 inch thick cedar boards notched and fitted to drywall jambs.

For door jambs, we chose 2 inch thick cedar on edge, to match the cedar trim on the exterior. A few more details came later, including the entry way bench, refrigerator surround, and tilework.

April 2, 2025 marked the day the keys were officially turned over to the homeowners, JC and Laura Love. What a rewarding time is was to put into place all the architectural elements that make up this home’s basic character. Now, the Love’s will add their artwork, furniture pieces, and other tools for living that will make it truly their own!