April 2, 2025: We never, ever had a dumpster at our construction site. Of course, we had our share of waste: this is America and things tend to come well packaged. But, we never resorted to a dumpster and never paid someone to haul our trash away. How did we do it?

This is not ours. It’s from a new home construction site similar in size and type to ours. The Environmental Protection Agency has estimated that the construction of a typical 2000 square foot new home generates 4 tons of waste, or about 4 pounds per square foot. Four tons can fit into a typical 40 yard dumpster.

We saved at least $850 by not renting a dumpster.

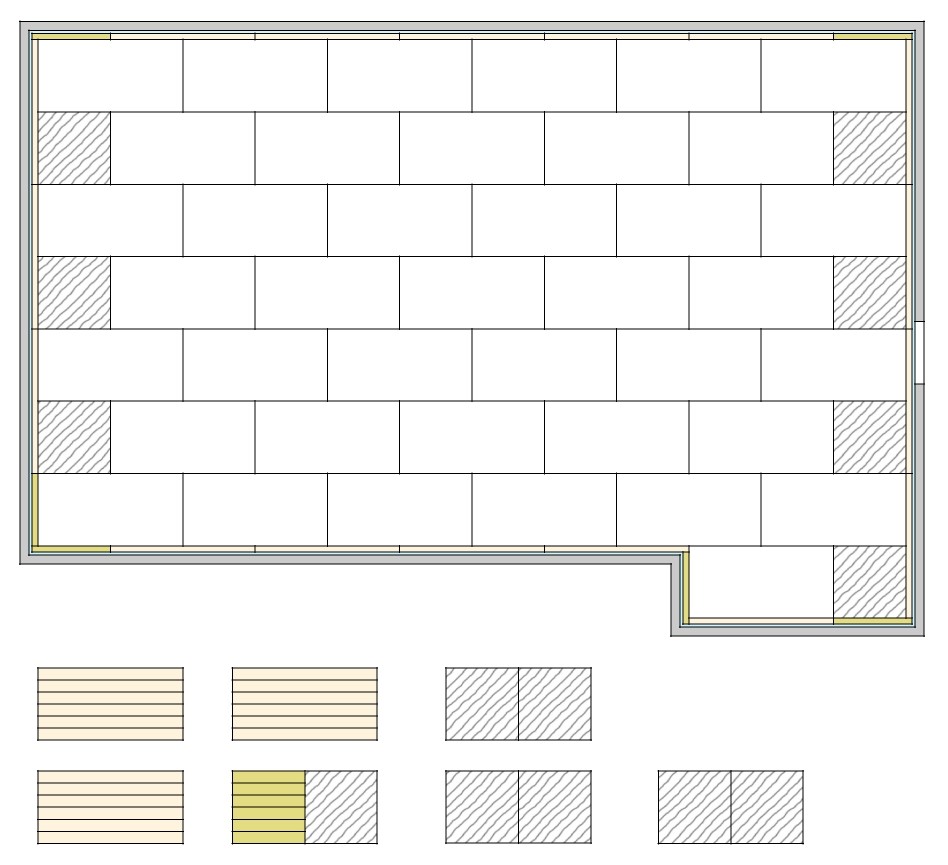

Preventing waste starts with a design that’s simple in shape and proportioned to work with conventional building materials that are sold in 2 foot increments (think plywood, dimensional lumber, and siding). Before ordering materials, I worked out quantities and layouts so that instead of picking off the top of the pile, the crew had a clear plan for what pieces went where. Here is the Cut List for the under slab foam insulation. White 4×8 sheets are to be laid down full. Hatched 4×4 sheets offset the pattern so that edge seams jog for enhanced air-tightness. Yellow sheets are to be ripped for the perimeter. See my blog post Insulated Concrete Slabs.

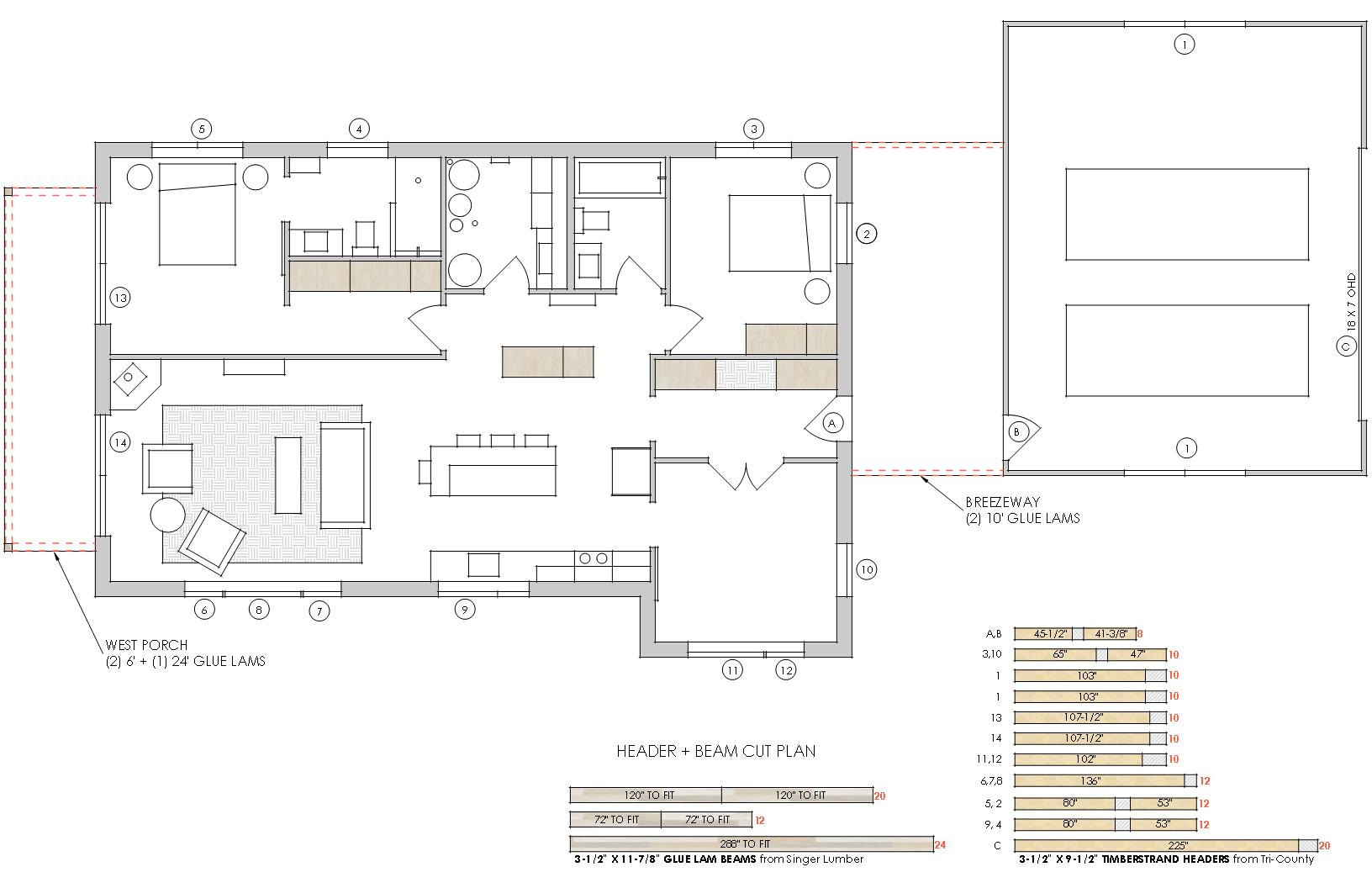

Another Cut Sheet shows the Engineered Lumber headers and porch beams keyed to the floor plan for proper placement. These babies are expensive, so I carefully worked out what lengths to order. The lead time scared me: the carpenters couldn’t make any mistakes or we’d be set back several weeks. This example of “just-in-time” material sourcing can reduce waste by keeping everyone on their toes and by minimizing damage to material that sits around the job site too long. See my blog post Exterior Framing.

For other good ideas, see the book I’m reading Building an Affordable House by Fernando Pages Ruiz.

The garage became the holding place for scrap wood. We had a lot of 2×4 “shorts” partly because instead of running a second top plate for the 9 foot tall interior partition walls, I ordered 10 footers—still a savings in lumber. We used some shorts for blocking and to build insulated can light boxes. The rest were gifted to friends who heat with wood in the wintertime or who like camp fires.

The HVAC and plumbing contractors requested some kind of solid backing in the mechanical room to hang their equipment. We used plywood scraps for blocking between the studs, prior to hanging drywall. We stockpiled every scrap until the bitter end, when we finally hauled them off to a nearby recycling facility.

Cardboard is a no-brainer. There was a lot of it. Every box was broken down and set out for recycling.

Plastic is hard. I couldn’t find a recycling facility nearby to take sheet foam or rigid packaging foam, though I know there are places out there. Plastic wrap and shrink wrap was readily accepted, if clear. Plastic ties and zip ties, no.

Metal is easy. Both painted aluminum (like this soffit material) and galvanized metal (like this flashing) is readily accepted. Cement board siding, while mostly biodegradable, is not.

I have a confession to make: the construction debris I wasn’t able to recycle ended up surreptitiously slipped into my household trash, in heavy-duty black plastic bags—-just one or two every few weeks so as not to raise alarms. It’s a fudge I justified by keeping the volume very low.

Some environmentally-minded builders go to great lengths to set up recycling bins at their job sites or have meetings or put language in their contracts requiring subs to recycle, but that wasn’t my style. Instead, I made it my job to clean up the job site everyday, to sort and stack, to separate and surreptitiously slip. I wasn’t above digging through the trash to retrieve a pop can tossed in by a sub.